详细信息

视频列表

(1) Equipment introduction

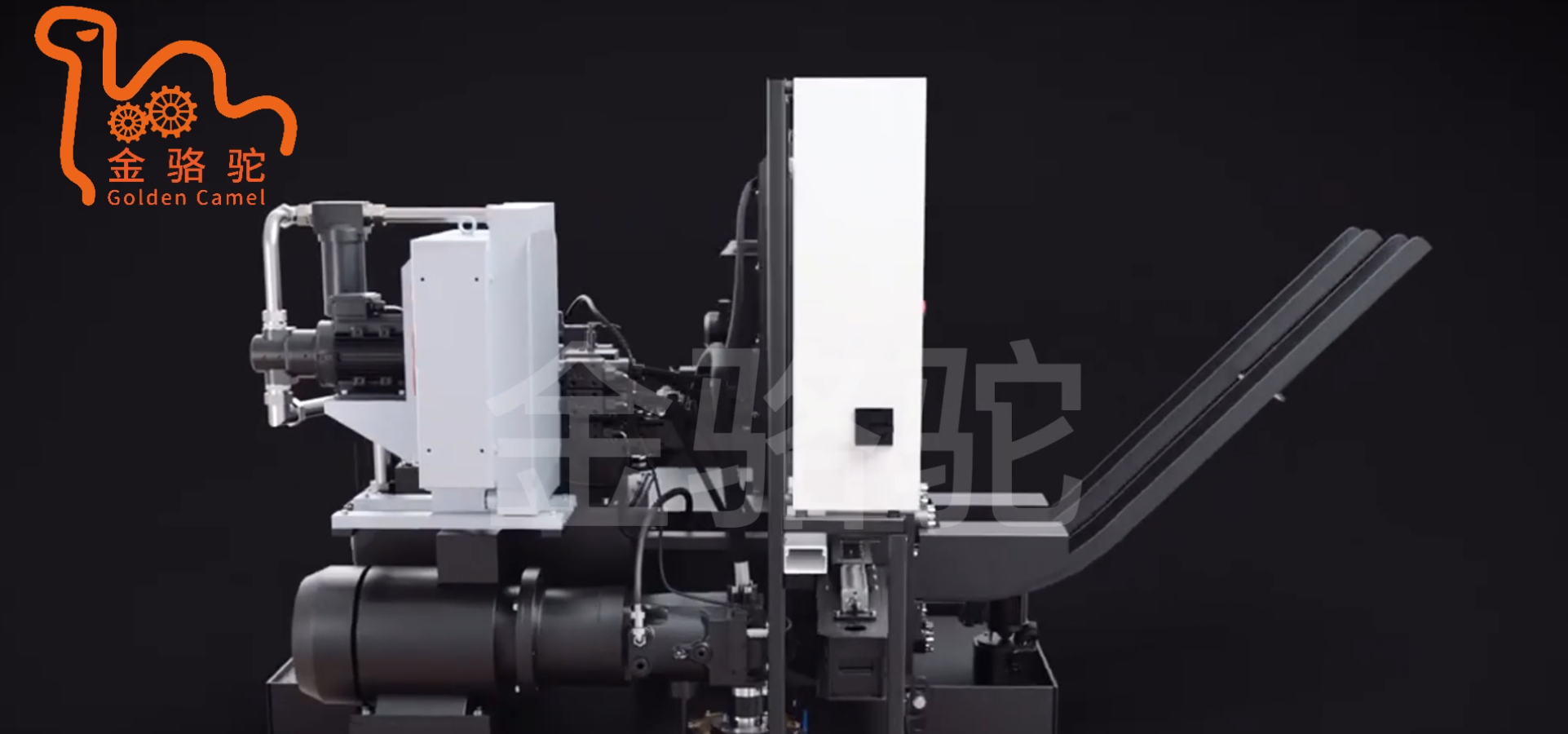

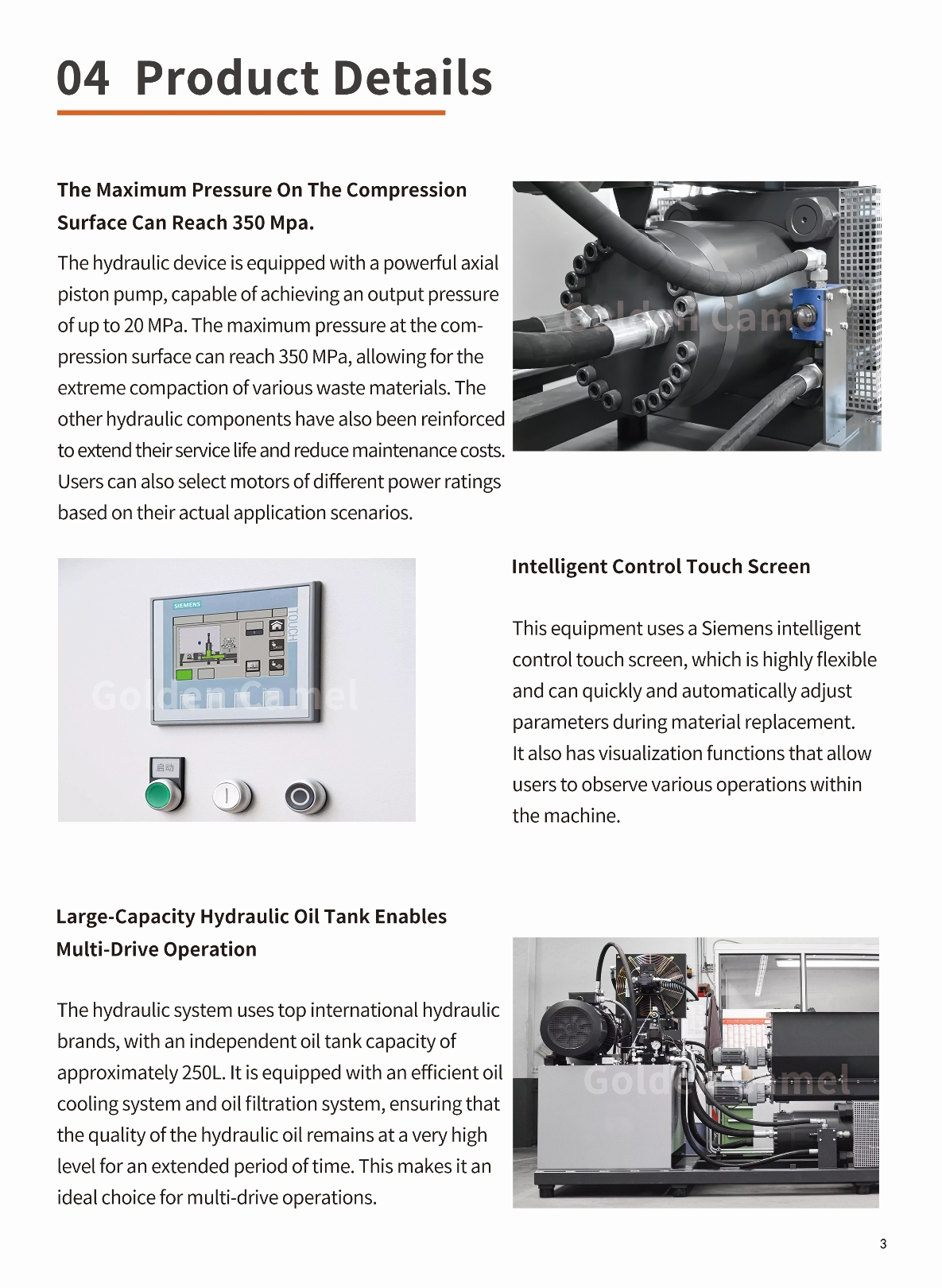

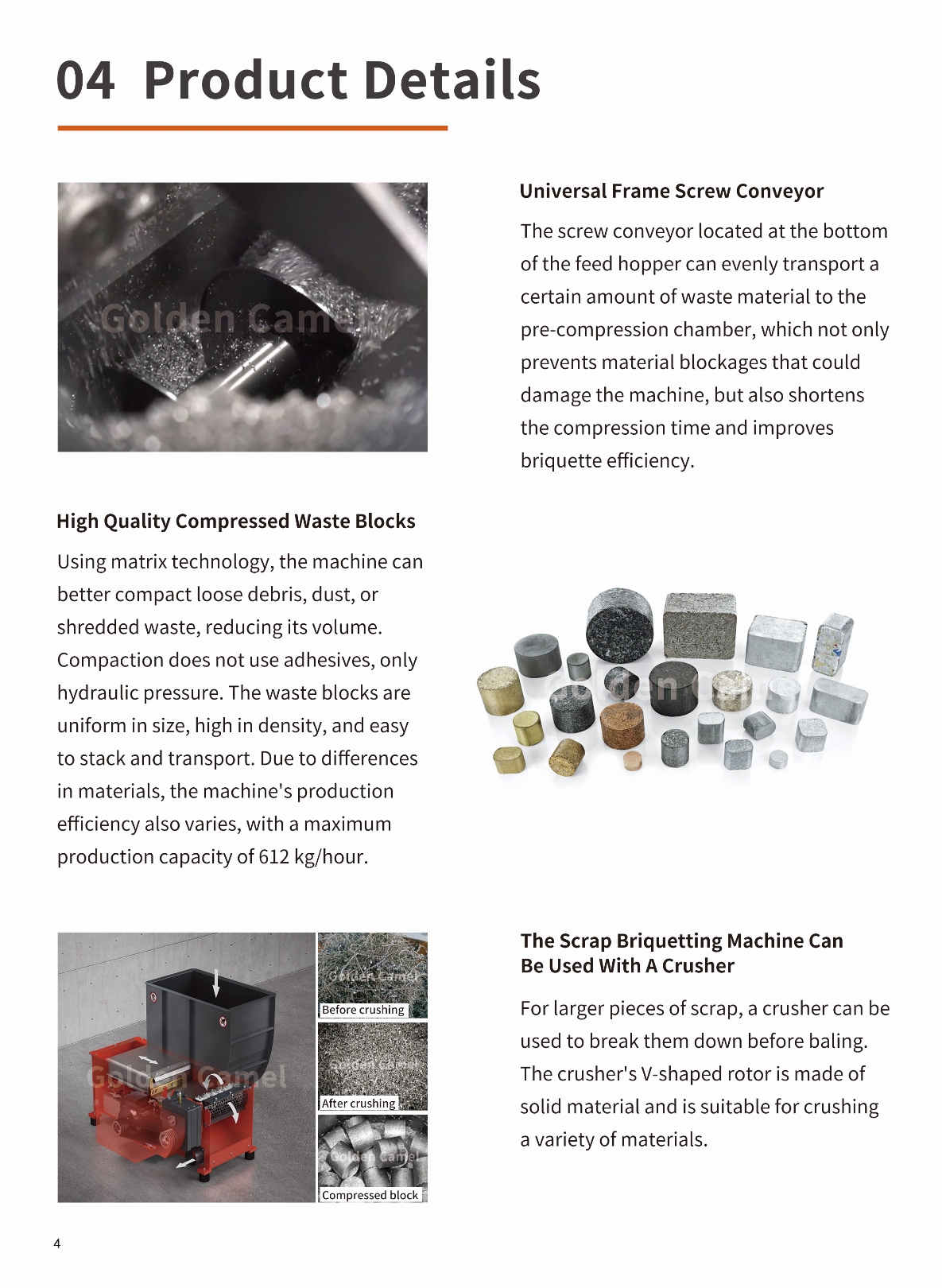

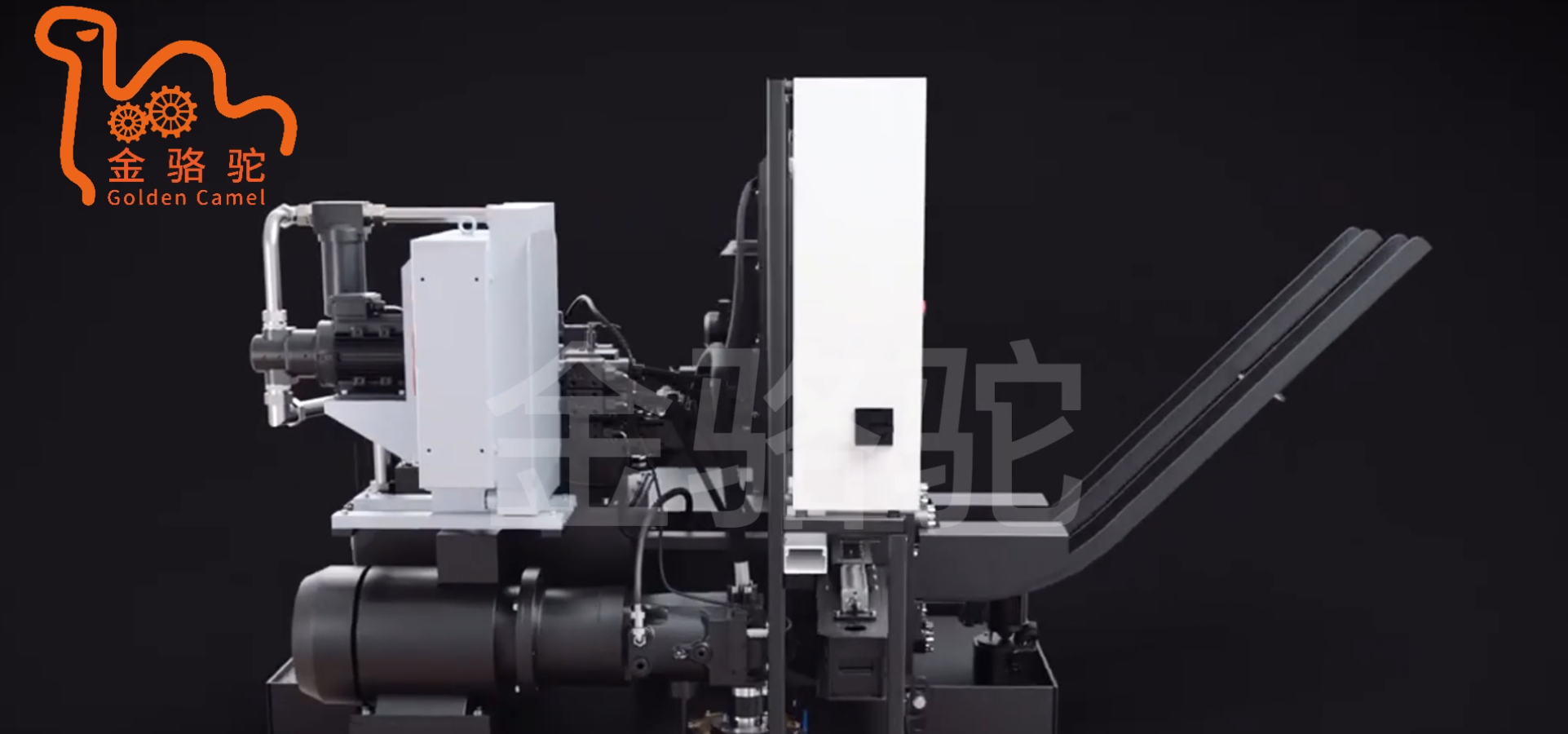

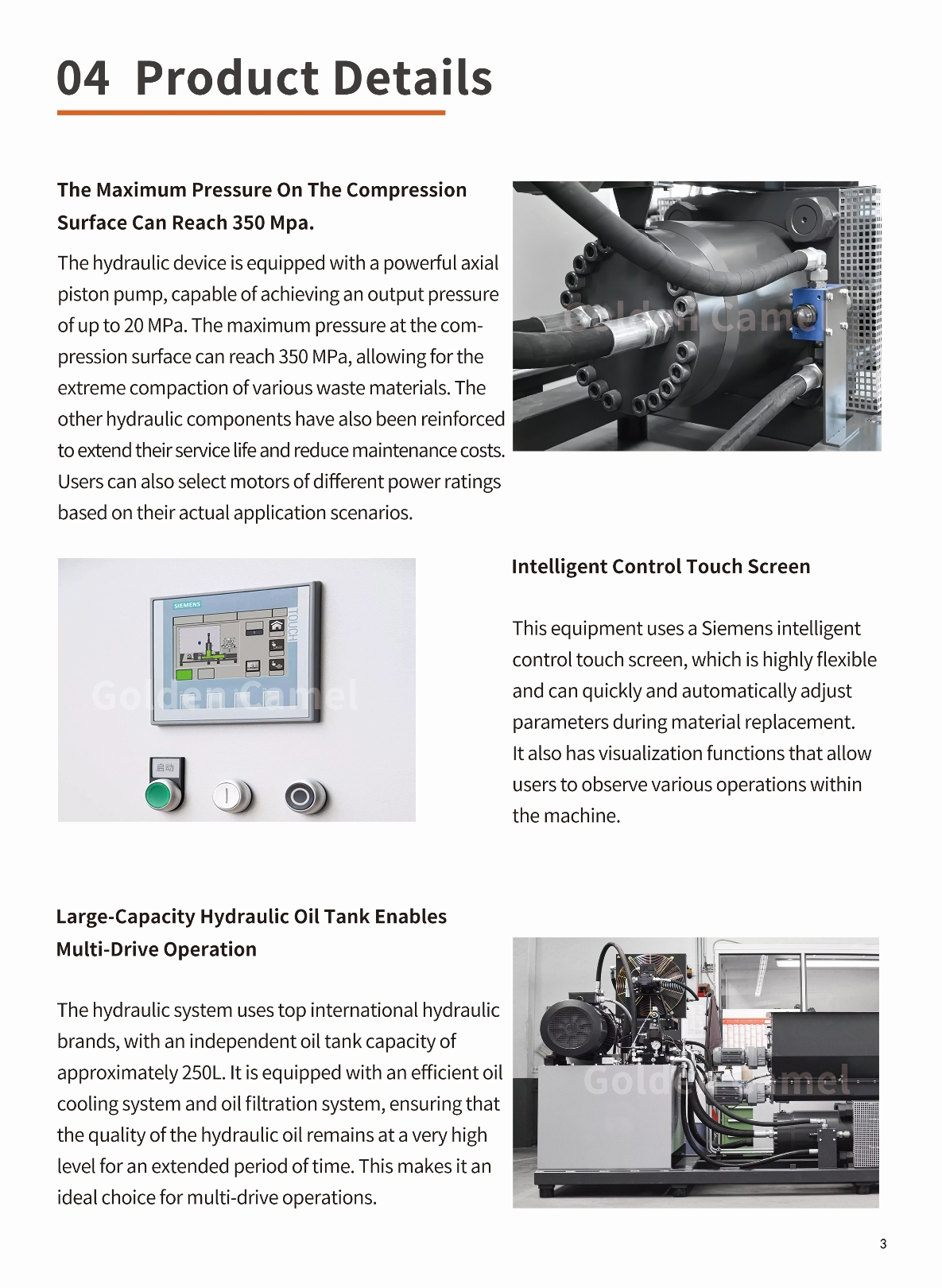

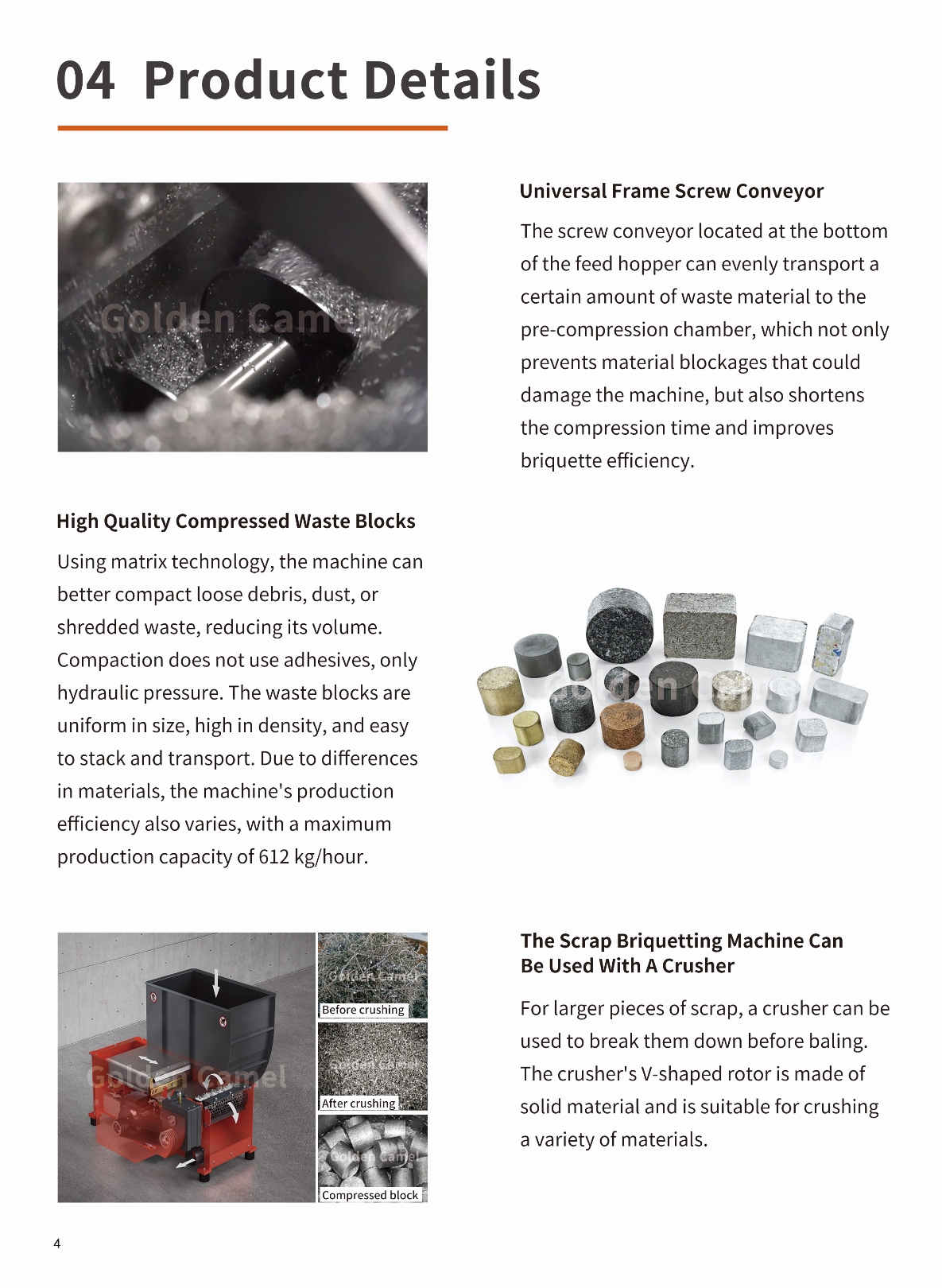

The powerful axial piston pump output system pressure of the hydraulic device of the equipment can reach 25Mpa, and the maximum compression surface pressure can reach 351Mpa. Compaction does not use any adhesive, only hydraulic pressure; The waste blocks produced by the equipment are uniform in size, high density, easy to stack and transport, and there is also a gap in production capacity according to different materials, with a production capacity of up to 300 kg/h;

The equipment is equipped with a universal interface, which can be quickly assembled into the existing production line, the machine is equipped with an intelligent control screen, the production parameters can be flexibly adjusted, and various operations in the machine can also be visualized; The rest of the hydraulic components have also been strengthened to extend their service life and reduce maintenance costs; Users can also choose motors of different power according to actual application scenarios;

(2) Applicable fields

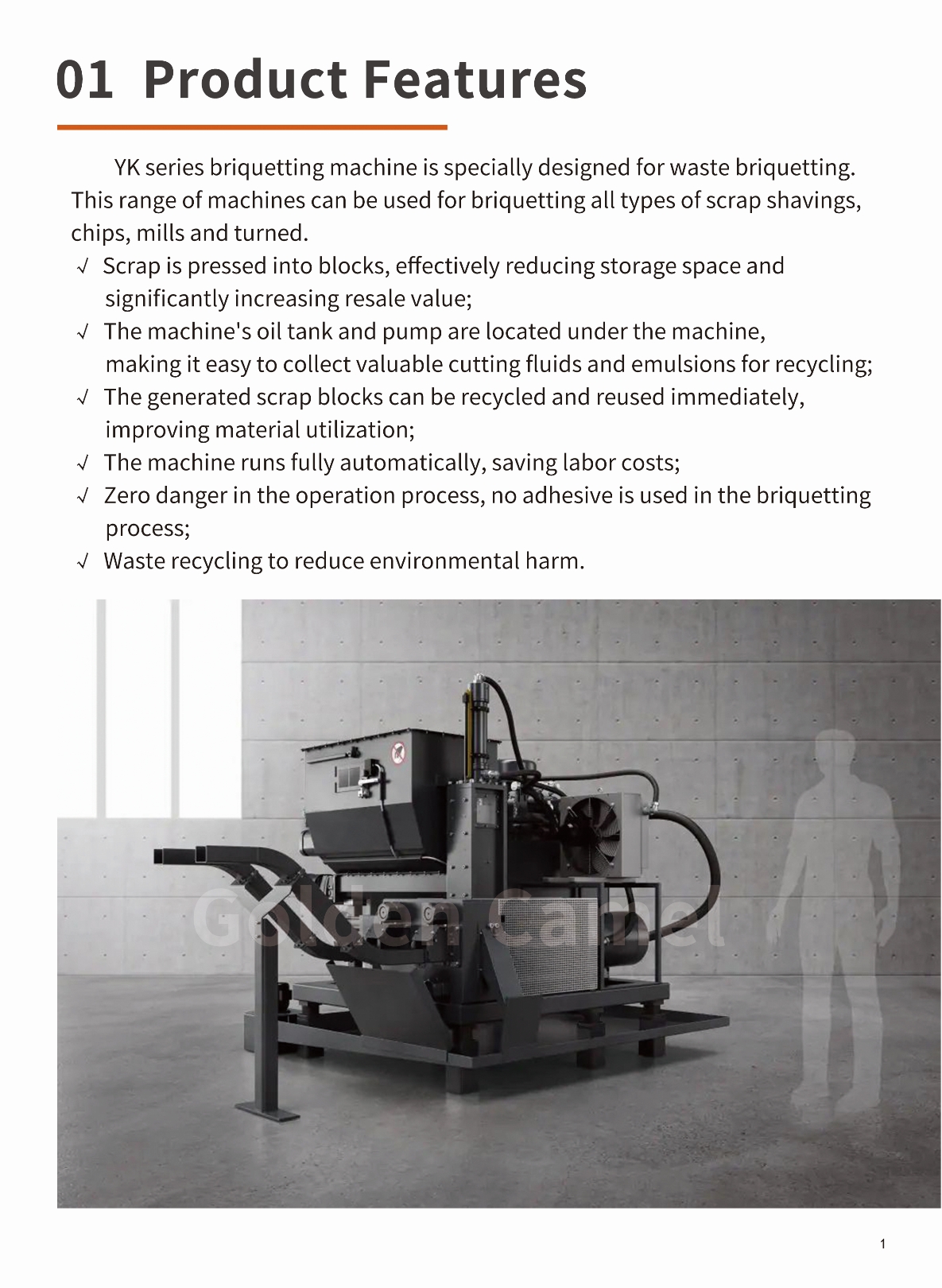

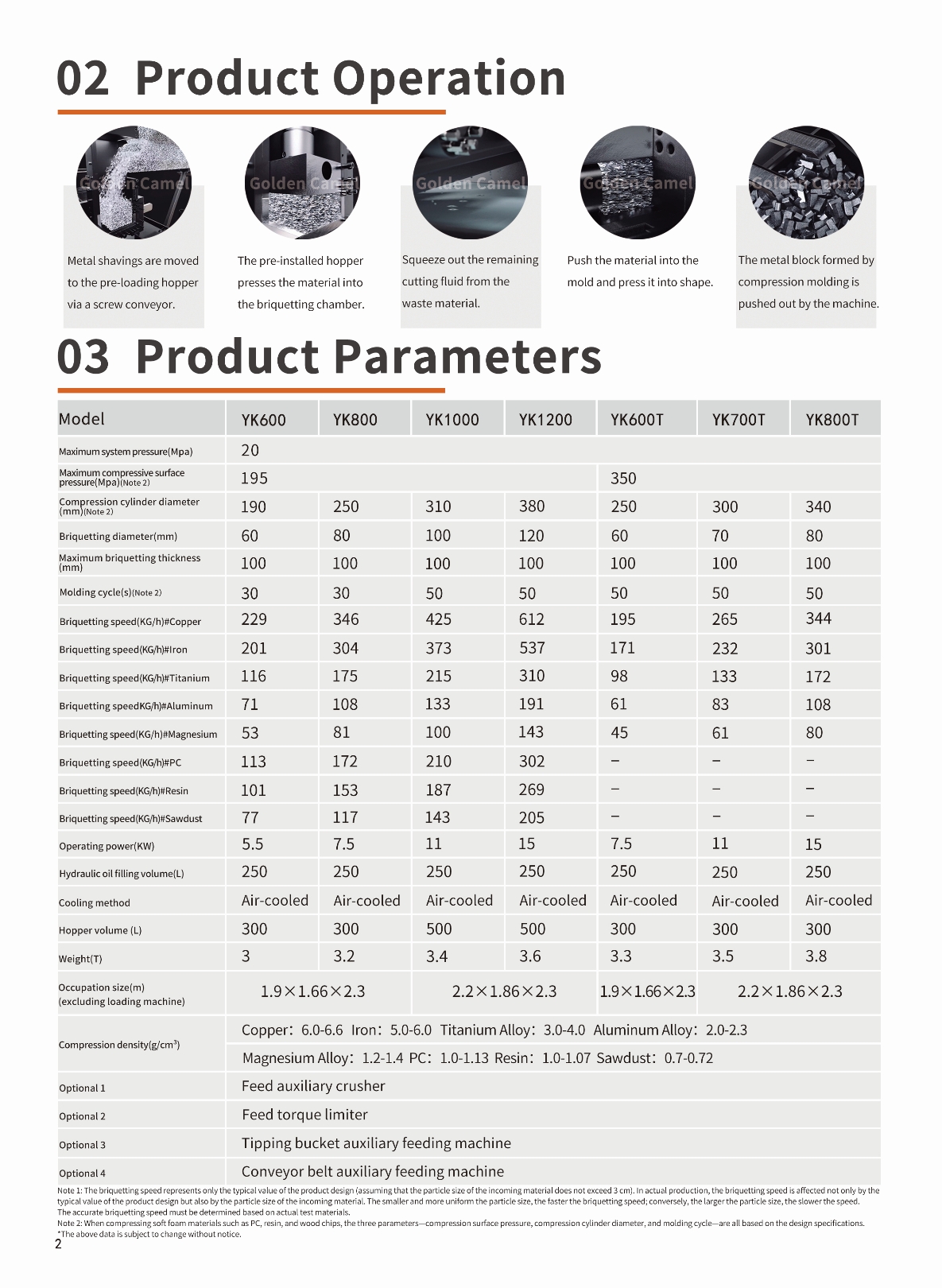

The scrap briquetting machine can be used for briquetting forming all types of scrap shavings, chips, grinding and turning;

(3) Product features

1. Pressing the waste into blocks, effectively reducing the storage space and significantly increasing the resale value;

2. The oil tank and pump of the machine are located under the machine, which is easy to collect valuable cutting fluid and emulsion for recycling;

3. The output of the waste block can be recycled to improve the waste recovery rate;

4. The machine runs fully automatically, saving labor costs;

5. Do not use any adhesive in briquetting and operate with zero danger;

6. Waste recycling to reduce harm to the environment;